When passengers pass through the newly remodeled Portland International Airport in spring 2024, they’ll be able to point up to specific Douglas fir beams around the oval skylights and know that they came from the ancestral lands of the Coquille Indian Tribe in Southwestern Oregon.

This will be the first major US airport to have a mass timber roof, and all the timber for the project came from sustainably managed forests that are located less than 300 miles away. The soaring, nine-acre ceiling — which will have lots of natural sunlight streaming in through the skylights and windows — will feel a bit like a forest. (The renovation will also include the addition of 70 or so living trees that will be growing in recessed and above-ground planters.)

The process of sourcing the wood took six years of planning, research, forest visits and many, many phone calls between the Port of Portland, Portland-based ZGF Architects, regional tribes, family-run forests, mill owners and brokers.

When ZGF principal Jacob Dunn joined the firm in 2017, his colleagues were already considering going with an all-wood roof. The Port of Portland, the public authority that oversees the airport and marine terminals in Portland, loved the idea. “The Port’s mandate was: We want it to be a mass timber roof. We’re the front door to the region, we really want to showcase this industry that is critical to managing and stewarding one of our region’s most precious natural resources,” recalls Dunn, who is ZGF’s sustainability lead for the PDX airport project.

The Port of Portland also wanted the roof to be the most sustainable version of a mass timber roof that it could possibly be — which meant traceability. “Most of the voices in the room said, ‘That can’t be done, that’s not the way the industry works,’” Ryan Temple, founder and owner of Sustainable Northwest Wood recalls. He was one of a handful of people who said that not only was it possible, it might even help redefine the timber industry — by making timber more traceable. He saw the project as a chance to identify and celebrate the people who are sustainably managing their forestland.

This ambitious goal meant that Dunn’s first task was to figure out the answer to a big question: “What is sustainable forestry?” He knew that the supply chains that come with concrete and steel are resource- and energy-intensive. (Steel relies on either mining or melting down existing steel; concrete is made of cement, water, sand, and gravel. Cement comes from mining and heating limestone, iron ore, and other materials to high temperatures, which releases large amounts of CO2 into the atmosphere.) With wood, there was an opportunity to find regional landowners who practice regenerative and restorative forestry.

“So it’s just a very vibrant, ecologically diverse forest. And that unlocks all the superpowers of a forest’s ability to clean air, clean water, provide habitat, provide carbon sequestration, fire resilience. It all comes down to diversity,” Dunn says.

What Dunn learned during that time boiled down to three main tenets for maintaining the diversity of natural forests: Make smaller harvests, cut down older trees and leave more trees behind.

In Oregon, the legal maximum for a clearcut is 120 acres. (In Washington, the maximum is double that in most cases.) If you cut, say, 30 acres, you’re leaving a patchier forest, which has more diversity. And while cutting older trees might sound counterintuitive, Dunn notes that this doesn’t mean true old growth — which generally refers to trees over 150 years old — but rather trees that are “slightly older”: Typically, Douglas firs are cut down at 40 years old.

“We want it to be more like 60 years,” Dunn says, “which would actually make a big difference in terms of the maturity of that forest, the complexity of that stand.” Anything beyond 80 years, Dunn says, sustainable foresters will conserve.

Leaving more trees behind, known as “wildlife tree retention,” means there’s more continuity in the environment as the next stand grows up, from the soil biota to the overall functioning of the ecosystem. In Oregon, on any clearcut over 25 acres, foresters are required by law to leave two live trees or two standing dead trees (known as “snags”) on average per acre, which means less than one percent. (The trees or snags must be at least 30 feet tall and 11 inches in diameter.) Snags, even though they are dead, provide important habitat for owls, woodpeckers, bats, squirrels, raccoons and other wildlife. Ecological forestry standards, on the other hand, leave behind 30 percent of the living trees, says Dunn.

That clearcut produced 40,000 board feet per acre, which is 30 to 50 percent higher than what a typically managed forest would yield. “Not only is this higher ecological functioning,” says Dunn. “But they are getting more wood out of that because that’s how the tribe has been managing it for a long time. It’s the best of both worlds.”

The Skokomish tribe also went well beyond these tenets. When ZGF and the Port of Portland’s teams went out to the forest, they met with CEO Thomas Strong who showed them how the tribe does low-impact forest restoration. “They were looking at almost single tree removal and restoration, which was still producing a fair amount of wood that could go into something like the airport,” Dunn says. When he says “almost,” what Dunn means is that the tribe never cuts down two trees right next to each other. So even if they cut down, say 20 trees per acre, it still looks like a forest.

Weighed down by negative news?

Our smart, bright, weekly newsletter is the uplift you’ve been looking for.The Oregon white oak being used on the concession pavilion walls came from a small family forest called Elkton Reserve. This was a case where the wood required no cutting at all: “They had a bunch of blow-down trees,” says Temple of Sustainable Northwest Wood, referring to trees that blew down in a windstorm. “It’s being cut into quarter-inch strips and pressed onto the cross laminated plywood, which is being used for the airport roof.” Even the white oak flooring in this new wing of the airport will be from local regeneratively managed forests: Zena Forest, 70 miles away, west of Salem, and a handful of neighboring forests that are also carefully managed. For over three decades, Zena Forest’s 1,300 acres have been cared for by the Deumling family, who believes that a mixed-species and mixed-age forest creates greater resilience.

Ecological forestry almost always privileges the landscape over financial gain. But buying wood from local, regeneratively managed forests tells a story about landowners who want to make a living and preserve forest ecology at the same time. Was Port of Portland able to pay a premium for wood that came from these forests? Because wood is a commodity, it is indexed at a certain price. That means if you’re a landowner who practices ecological forestry, you’re selling the wood into the market at the same price as an industrial landowner who is doing the maximum acres of clearcut allowed by law.

“It’s all blended, so there’s no way for us to get the premium to them,” says Dunn. But ZGF was able to buck that trend in at least one instance. Sometimes timber goes through a silent auction. “We talked to the mill that was going after the Skokomish wood and we said, ‘We know they’re doing fantastic forestry, we love their equity story, we want to incorporate more tribal wood. Please go bid on the timber sale. And please be competitive.” Tacoma-based Manke Lumber did — and they upped the bid at the last minute so they ended up getting the sale.

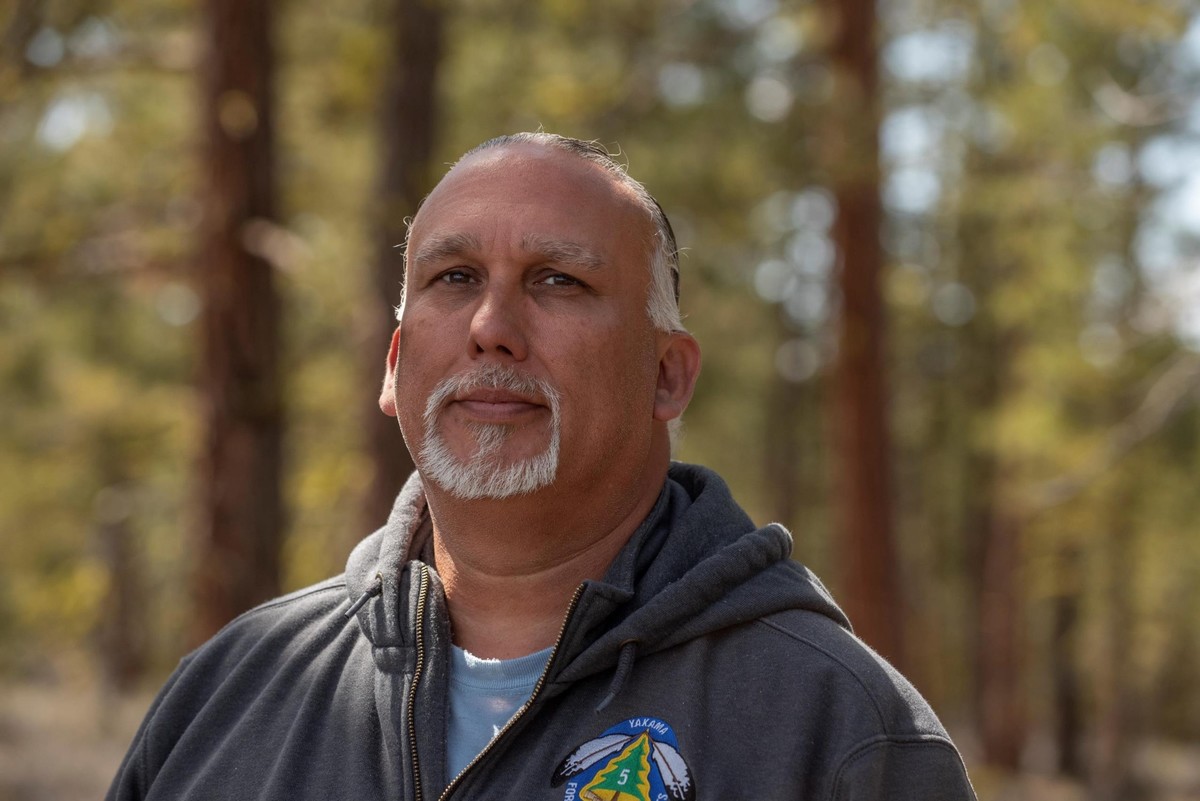

The Yakama Nation, which is a confederation of 14 bands and tribes, has 600,000 acres of forest in the Eastern Cascades, of which 450,000 is used for commercial forest activities. For Steve Rigdon, general manager of Yakama Forest Products (a chartered Yakama Nation enterprise) this project was an opportunity to tell the story of his people’s tribal land, which is managed to mimic the natural disturbances and tribal practices that have historically occurred there.

“We are part of an ecosystem that is very fire intensive,” Rigdon says. “If there were fires that came in more frequently and spaced the trees out more, we’ll thin it heavily there. If we’re on a north-faced slope with more shade and moisture, we won’t thin it as heavily there.” (The Yakama Nation Tribal Forestry and Bureau of Indian Affairs Forestry staff do the forestry work, but Yakama Forest Products oversees the loggers who harvest the trees.)

They also try to mimic the forest ecology practiced by their ancestors for travel, grazing, foods and medicine. For example, the tribes on this land have historically orchestrated controlled burns to enhance the growth of huckleberries, which are both a sacred food and medicine. So today, in addition to controlled burns, tribal foresters will cut back the trees near huckleberry fields. The same thing happens when trees encroach into their meadows, sucking up the water and sunlight that they rely on for their wild onions, wild carrots and bitterroot. “So we’re taking that life of the tree and honoring it and making it a product,” Rigdon says. “And those products pay for our jobs.” Yakama Forest Products’ mill provides nearly 200 jobs in the White Swan, Washington community.

Yakama Forest Products provided 370,000 board feet for PDX’s Glulam beams — a glued laminated timber material that’s said to be stronger than steel. This was the largest fiber contribution of any of the landowners involved.

The process of engaging the timber supply chain in a unique way was a revelation for Dunn and for ZGF. “It really made us understand the impact of our procurement decisions. Connecting back to the land that created it. Understanding social histories, the economic histories of the timber industry in the Pacific Northwest, which is very rich, colorful and controversial in some cases,” Dunn says.

He says one of his greatest fears in life, now that the airport is done, is that it will be a “monument to the unattainable”: “Everyone will be like, ‘What the airport did was great, but we can’t do that for this office building project.’” To encourage more locally-sourced timber buildings, Dunn has taken on a new role at ZGF to integrate a similar approach with future projects. Already, two new clients — well-known tech companies — are trying to do direct sourcing to make sure all of their wood comes from tribal lands or other regeneratively managed forests. “We’re also working across the industry to where every project could ask for the tracking and transparency data,” Dunn says. “So we’re all asking the supply chain for: we want to know where our wood comes from. That’s the level of market transformation we want to get to.”