Last month, a small warehouse in the English city of Nottingham received the crucial final components for a project that leverages the power of used EV batteries to create a new kind of circular economy.

Inside, city authorities have installed 40 two-way electric vehicle chargers that are connected to solar panels and a pioneering battery energy storage system, which will together power a number of on-site facilities and a fleet of 200 municipal vehicles while simultaneously helping to decarbonize the UK’s electrical grid.

Each day Nottingham will send a combination of solar-generated energy — and whatever is left in the vehicles after the day’s use — from its storage devices into the national grid. The so-called “vehicle to grid” chargers deliver this energy just when it’s needed most, during peak evening demand, when people are home cooking, using hot water or watching TV. Later, the same chargers pull energy from the grid to recharge the vehicles in the wee hours of the night, when folks are sleeping and electricity is cheaper and plentiful.

“We are trying to create a virtual power station,” says Steve Cornes, Nottingham City Council’s Technical Lead. “The solar power and battery storage will help us operate independently and outside of peak times, making our system more resilient and reducing stress on the national grid. We could even make a profit.”

What makes the project truly circular is the battery technology itself. Funded by the European Union’s Interreg North-West Europe Programme, the energy storage system, E-STOR, is made out of used EV batteries by the British company Connected Energy.

After around a decade, an EV battery no longer provides sufficient performance for car journeys. However, they still can retain up to 80 percent of their original capacity, and with this great remaining power comes great reusability.

“As the batteries degrade, they lose their usefulness for vehicles,” says Matthew Lumsden, chairman of Connected Energy. “But batteries can be used for so many other things, and to not do so results in waste and more mining of natural resources.”

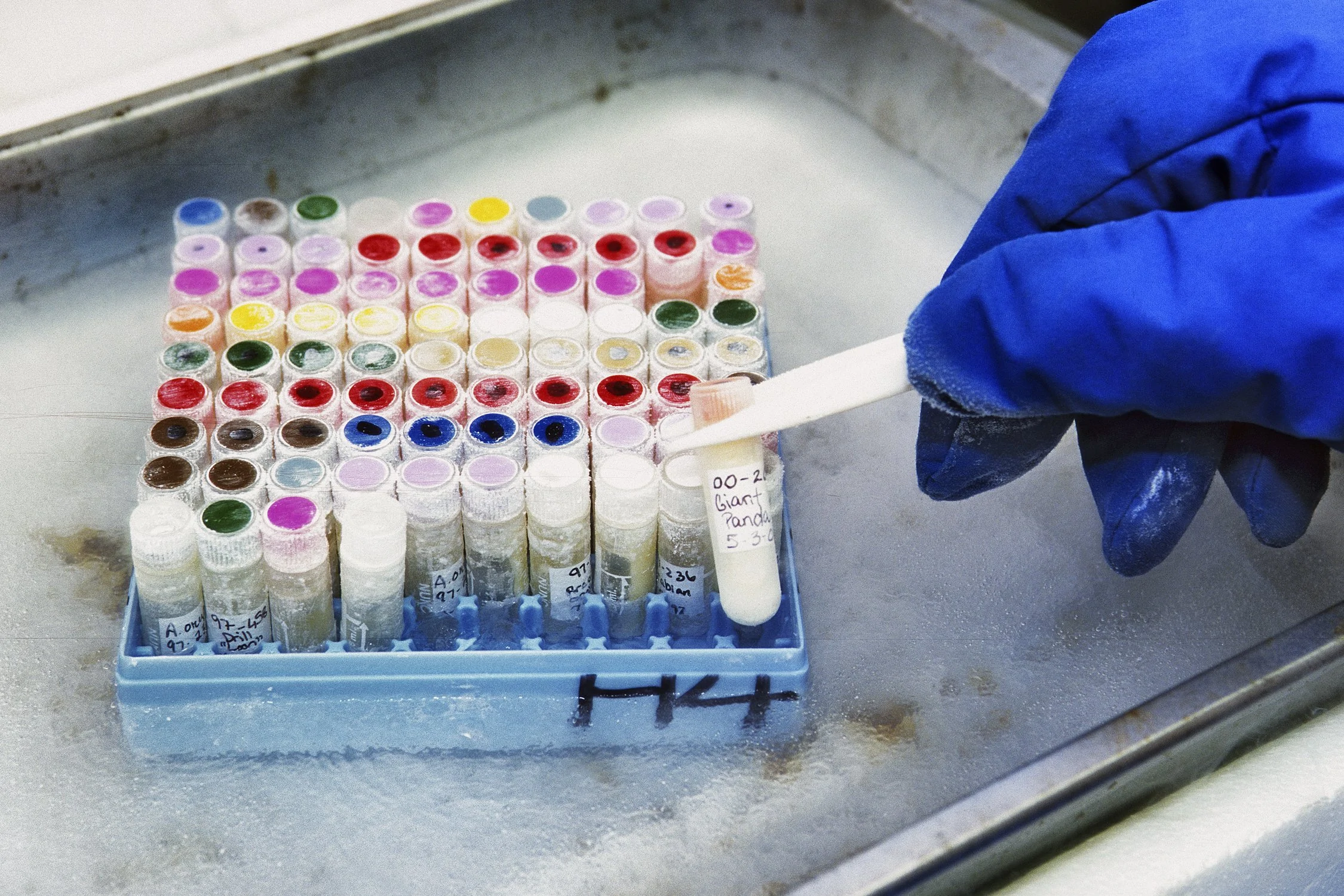

The E-STOR hubs come in the form of 20-foot modular containers, each one packed with 24 repurposed EV batteries from Renault cars. Each hub can provide up to 300kW of power, enough to provide energy to dozens of homes. One study by Lancaster University, commissioned by Connected Energy, calculated that a second life battery system saved 450 tons of CO2 per MWh over its lifetime.

The challenge with using second life batteries is that they are all slightly different, and in different states of health. “If you have 100 batteries in a system, and a certain amount of power is required, you need to pull slightly different energy from them,” says Lumsden. “Our control architecture is designed to do exactly that.”

Battery repurposing and recycling is set to play a massive role over the coming years as the automobile industry attempts to decarbonize and the world more broadly attempts to fight waste. The production of EVs, which use lithium-ion batteries, is accelerating. Tesla, for example, is aiming to sell 20 million EVs per year by 2030 — more than 13 times the current level. In turn, 12 million tons of EV batteries could become available for reuse by 2030, according to one estimate.

“Over the next decade we are going to see this gigantic wave,” says Jessica Dunn, a senior analyst at the Union of Concerned Scientists. “Companies are recognizing this is a necessary industry. They need to ramp up infrastructure for recycling and reuse.”

European regulations aimed at cutting emissions and reducing waste are bolstering the secondary battery market, according to Vasileios Rizos, head of sustainable resources and circular economy at the Center for European Policy Studies.

From 2024, for example, manufacturers in the EU will be required to provide battery passports, which display detailed information on the supply chain, use of the battery, and battery health, after a comprehensive battery policy was passed in December.

Europe’s recent energy crisis, which has seen electricity and gas prices rise 15-fold since early 2021, has also catalyzed demand for more independent energy networks, adds Rizos.

“There’s been an explosion of interest,” he says. “And this is just the beginning.”

The US is catching up. In January, the Department of Energy awarded $73.9 million in funding for research to 10 institutions, including Tennessee Tech University, to advance technologies and processes for recycling and reusing EV batteries. And a number of companies such as Redwood Materials, Li-Cycle, and Ascend Elements have been working on lithium-ion battery recycling research and development, with planned facilities in Nevada, New York and Georgia.

Weighed down by negative news?

Our smart, bright, weekly newsletter is the uplift you’ve been looking for.There are a broad range of “secondary” uses for EV batteries -- from energy storage to powering fixed infrastructure such as street lights or elevators -- that don’t preclude those batteries from eventually being recycled. “Should batteries be repurposed before recycling? I think so,” says Dunn. “It’s not an either-or situation.”

Dunn, however, says the traditional smelting method of recycling batteries -- putting them in a furnace and extracting the nickel and cobalt -- is problematic due to the emissions and the fact that chemicals such as lithium and graphite are lost. “That’s not what we want to see,” she says. But new forms of water-based recycling, which can extract up to 97 percent of the materials, are on the way, she adds.

Still, there have been some bumps in the road on the journey to battery nirvana.

Lumsden says that Connected Energy, which has deployed about 1,000 batteries over the past six years, has had to work hard to get vehicle manufacturers on board due to enormous changes in the automobile industry and issues around sharing intellectual property, which is needed to work out how to reconfigure the batteries.

“Manufacturers are going through massive changes, electrifying their fleets, but second life use has been relatively low on their agendas until recently,” he says.

Users may also face difficulties connecting to the system, which remains in its early stages. “It’s very cutting edge,” says Cornes. “It’s like a research project. Finding the right suppliers was a challenge.”

Nottingham’s depot had to undergo a massive power upgrade, requiring a 11,000 volt substation to be built to support all the power-hungry EV chargers. “The amount of power required could be a real problem for some projects,” says Cornes.

But those difficulties could soon be blown away by the turbo-charged growth of EVs, and in turn, the batteries used to power them. By 2030, the secondary lithium-ion battery recycling market is projected to be worth $24 billion.

“We won’t be throwing these batteries away in landfill,” says Rizos. “Just look at the market for second hand smart phones. Consumers, manufacturers and retailers will want to reuse them. There’s so much value still in them.”